A properly sweated joint will last for years, but a poor job can cost you in water damage.

Mastering a perfectly sweated copper joint takes a bit of practice. Be patient! Your first couple of attempts may not look beautiful, but soon you’ll be sweating copper that not only doesn’t leak but also looks good.

Here are the 4 basis steps:

- Use a wire brush to clean the pipe.

Clean down to bare metal (this is very important as your weld will not seal without it) - Apply flux paste.

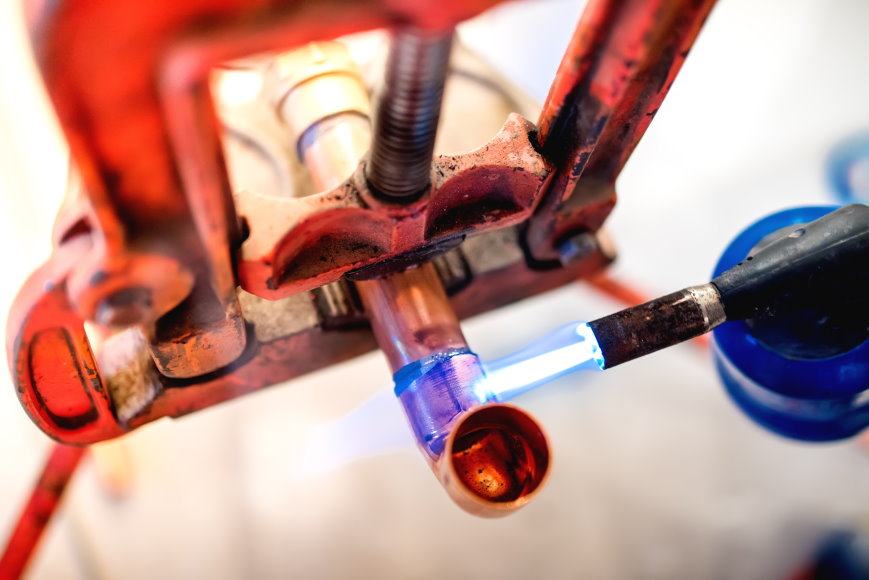

The flux paste ensures a clean surface for the solder. Apply with a brush to the inside and outside of the fitting and pipe. - Heat the fitting.

Use a handheld propane torch to heat the fitting. Just don’t get it so hot that you can’t hold it any more. Be very careful in tight spaces, and use a fireproof barrier if you are using the propane torch near wood or other flammable material. - Melt the solder wire and flux paste so that it flows into and fills the joint.

Finally, using the torch, melt the flux paste so that it flows into and fills the joint between the pipe and the fitting.

At Tim’s Plumbing Service, we do this all day long! Call us at 859-533-1294 and let us take care of your plumbing needs.